We may have a solution to a challenge you didn’t know you had.

Two of the largest investments an air cargo handler has are real estate and labor costs. Maxson Aviation Solutions & Service can assist you with reducing labor costs and maximizing the capacity of your facility through situational analysis and our diverse product line.

Case study: ULD Handling

ULD handling within an air cargo environment without an appropriate traffic flow plan can result in facility congestion and inefficient usage of labor resources. Improper handling techniques with the usage of forklifts can cause damage to cargo and the ULD’s and can have a negative influence on the timely movement of freight in and out of the operation.

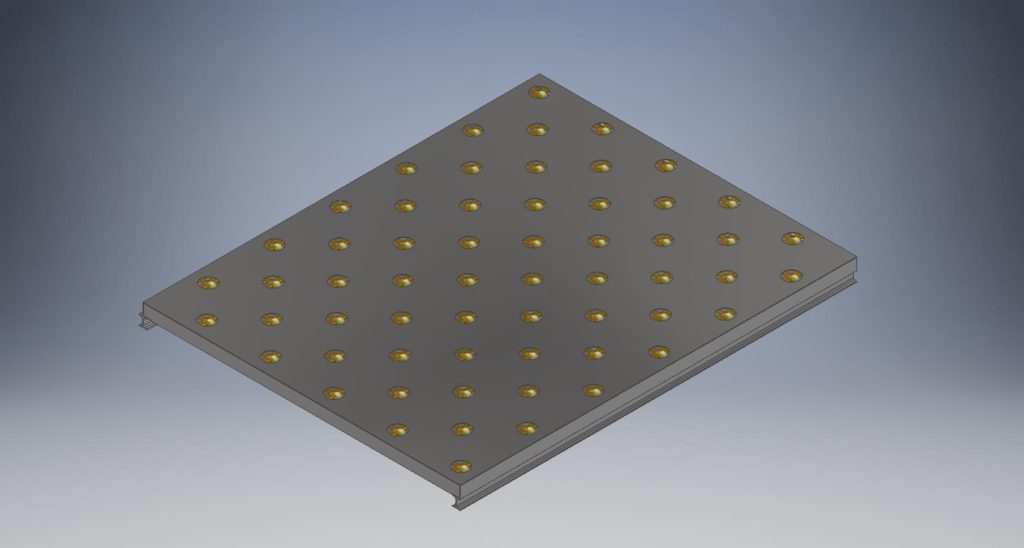

Maxson Aviation designs, manufactures and installs integrated caster deck handling systems that are engineered to provide a manual handling option for process BUP units, build-up and breakdown of ULD’s and ULD staging. These systems are very durable and require little or no maintenance as nothing is powered which eliminates the potential for damage or equipment failure.

We can custom design a system that integrates with your operational footprint and deliver to you a solution that will quickly provide you a return on your investment by increasing production and lowering the cost of your most expensive resource, your workforce.